Very slim X-ray tubes are used e.g. in nuclear plants to inspect weldings in narrow pipe to pipe space. Mobile X-ray systems up to 240 kV with high resolution guarantee high contrast images on film or digital imaging devices. Tubes for stationary cabinets or for online processes are optimized to inspect e.g. aluminum castings for cracks, voids and inhomogeneity.

The very first panoramic tire X-ray tube was introduced by rtw in 1974. The anode is 90° declined to the tube axis. Since then the tube could be inserted into the tire and examined the tire from bead to bead in one turn. A line scan camera is used to detect the steel and plastic cords. Today special designed tubes are produced to inspect the tires of motorbikes, cars, trucks and heavy earth movers. Flat target angles from 0° to 20° and conical targets with one or two or even three focal spots are available.

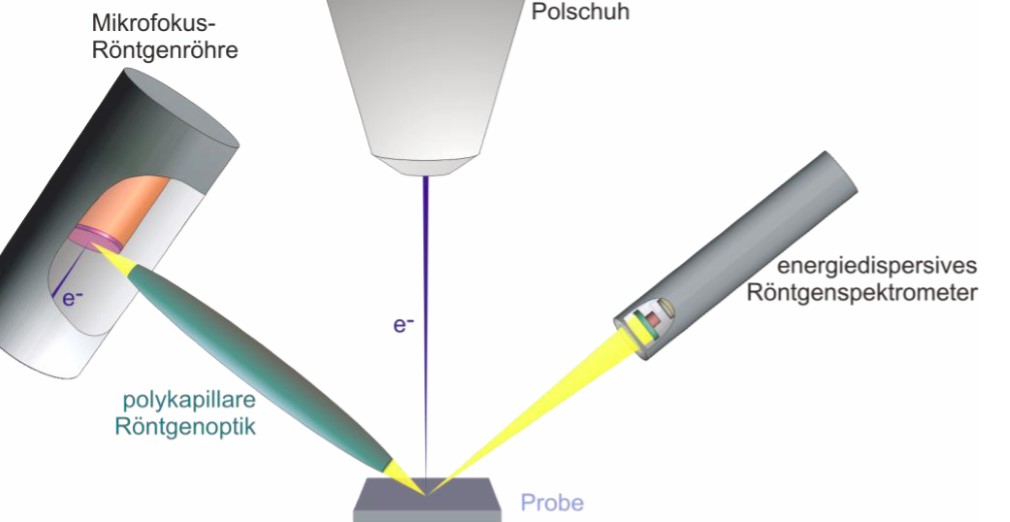

If material is radiated with X-rays fluorescence and reflection will appear. Modern systems are able to determine the constituents and their quantity down to the per mill range. The X-ray diffraction patterns allow to investigate the structure of their molecules. Very precise and stable focal spots on different target materials are indispensable. Together with X-ray mirrors, monocapillary, polycapillary or multilayer optics a 30 W rtw X-ray tube is comparable to a 3000 W one without optic.

X-rays are used in rough industrial online processes to measure the thickness of sheets and foils of different sizes and materials. The transmission through the material is precisely measured in the cold and hot milling process. The material gets rolled with 30 km/h and permanently controlled. The X-ray tubes are designed for ultra-stable emission output with high reliability.

Digital imaging, X-ray measurements, radioscopic applications or CT systems require small and brilliant focal spots and long lifetime. High emission filament design and electrostatic focalization with focal spots down to 50 µm are available. The rtw tube design reduces the dislocation of the focal spot on the target in long and short term conditions to a minimum.

Various food articles e.g. chocolate, jars with jam and baby food are controlled with fan beam X-ray tubes in digital inspection systems. High X-ray output and small focal spots ensure that metal parts, o-rings or broken glass are sorted out before shipment.

The inspection and measurement of small details is benefiting from the extreme ultraviolet light X-ray tubes. The wavelength of UV light is approximately 60 nm, as the wavelength from XUV tubes at 12 kV is 0,1 nm only. Low energy analytical applications with L and even M characteristic lines are made possible.

The electron beam is brought out through a thin, e. g. Ti, foil to irradiate surfaces of different shapes for sterilization or polymerization. Low energy sealed off tubes around 100 kV with different electron window designs are available.

For universities, institutes or for other activities trying a new approach in the X-ray field rtw is ready to develop new tube designs. Unique shapes and the adaptation of the tube parameters allow the OEM engineer to fulfill the market requirements.